Description

Why choose ToolSens8?

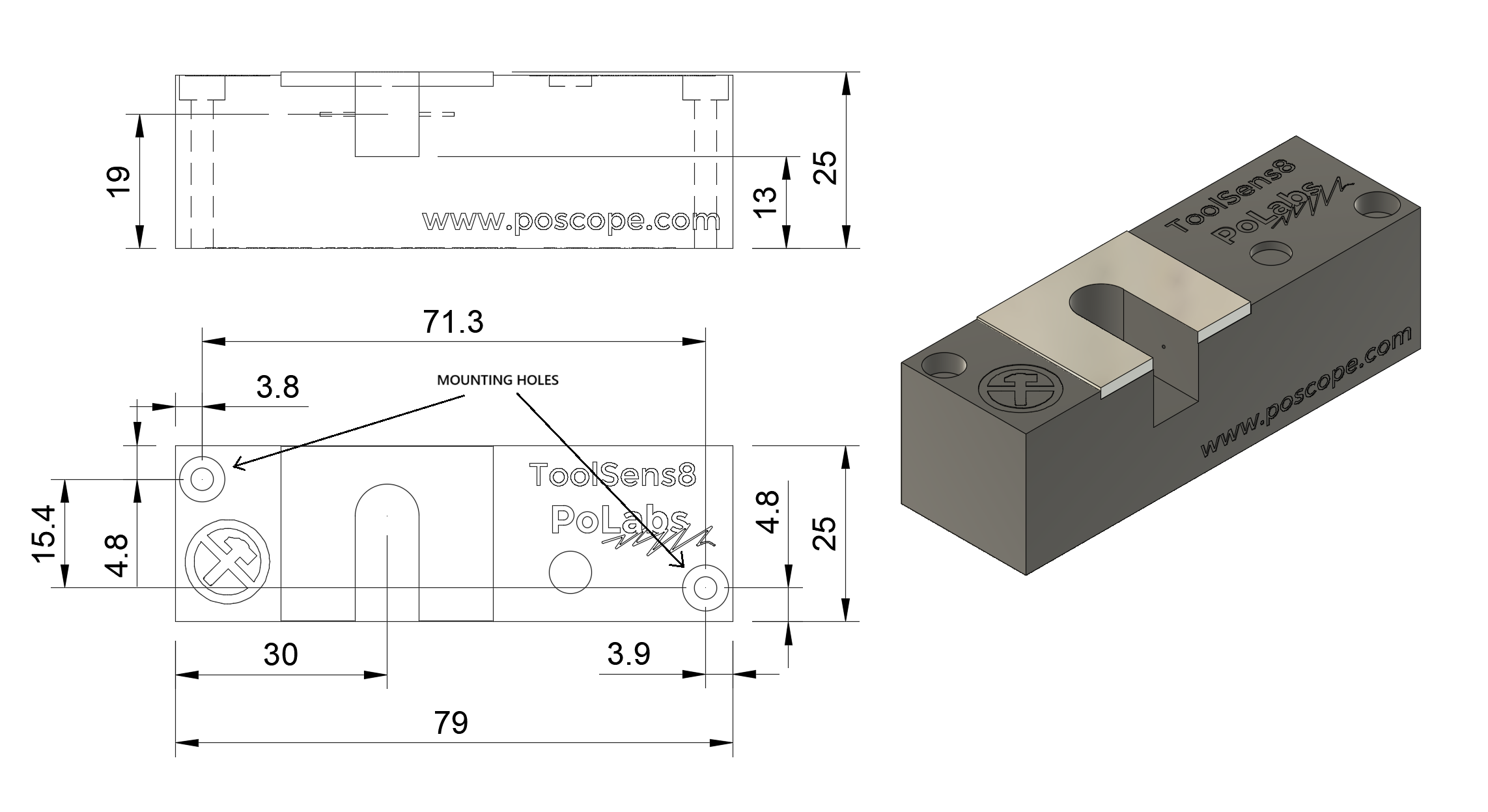

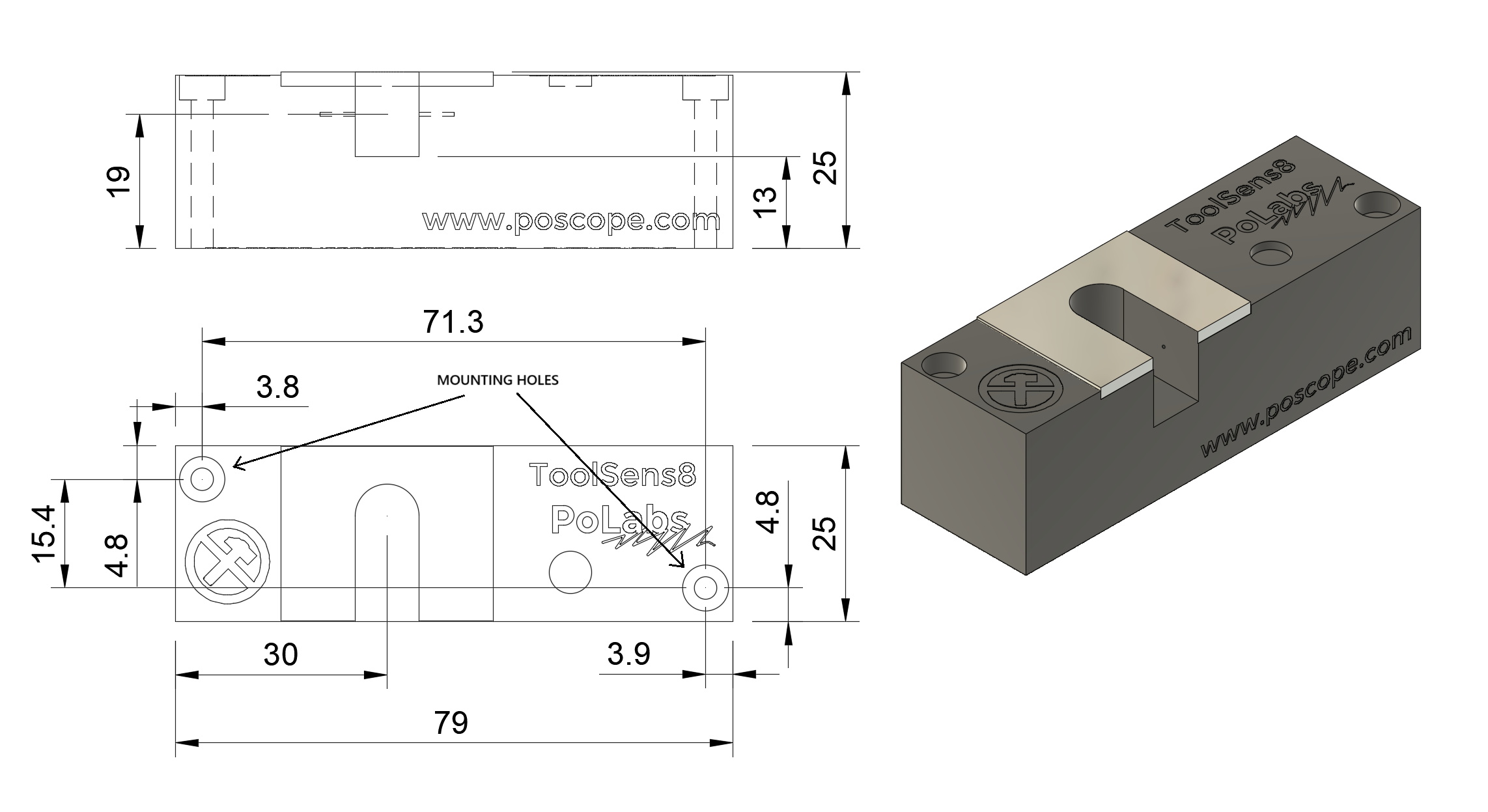

The ToolSens8 Laser Tool Measurement Sensor is a precision optical sensor designed for automated tool length measurement in CNC machines. The device offers a compact and accurate solution to ensure precise tool measurements during CNC operation and setup. It integrates seamlessly into automated machining systems to improve efficiency and production quality.

How can ToolSens8 benefit you?

In CNC operations, maintaining precise tool dimensions and positioning is critical to ensure consistent machining quality. The ToolSens8 sensor automatically detects and measures the tool length with a high degree of accuracy (±0.001 mm), eliminating manual inspection errors and reducing downtime. It can also measure diameter with advanced but intuitive probing cycles. Its non-contact laser measurement system enhances the longevity of both the sensor and the tools by minimizing wear and contamination. Non-contact means that it doesn’t need to touch the measuring surface, which means there is no risk of fracture of the already fragile cutting edge.

Technical specifications:

- Operating Temperature: 10℃ to 40℃

- Protection Class (IP): IP50

- Measurement Diameter Range: 0.05 mm to 8.00 mm

- Measurement Accuracy: ±0.001 mm

- Sensor Lifetime: 5 years (continuous operation, no external damage)

Benefits:

- No physical contact with tool — reduces wear and contamination

- Compact design suitable for integration into all kinds of CNC machines

- Increased production efficiency by automating tool measurements

- Reduced tool breakage and wear due to early detection of anomalies

- Enhanced product quality with consistent machining precision

- Lower maintenance cost due to laser sensor and increased tool life

- Simplified integration into existing CNC systems

Application examples:

Here are blog posts related to probing and tool setters. There are G-code examples as well as proper tool setting example with setting of tool offsets for CNC.

Reviews

There are no reviews yet.